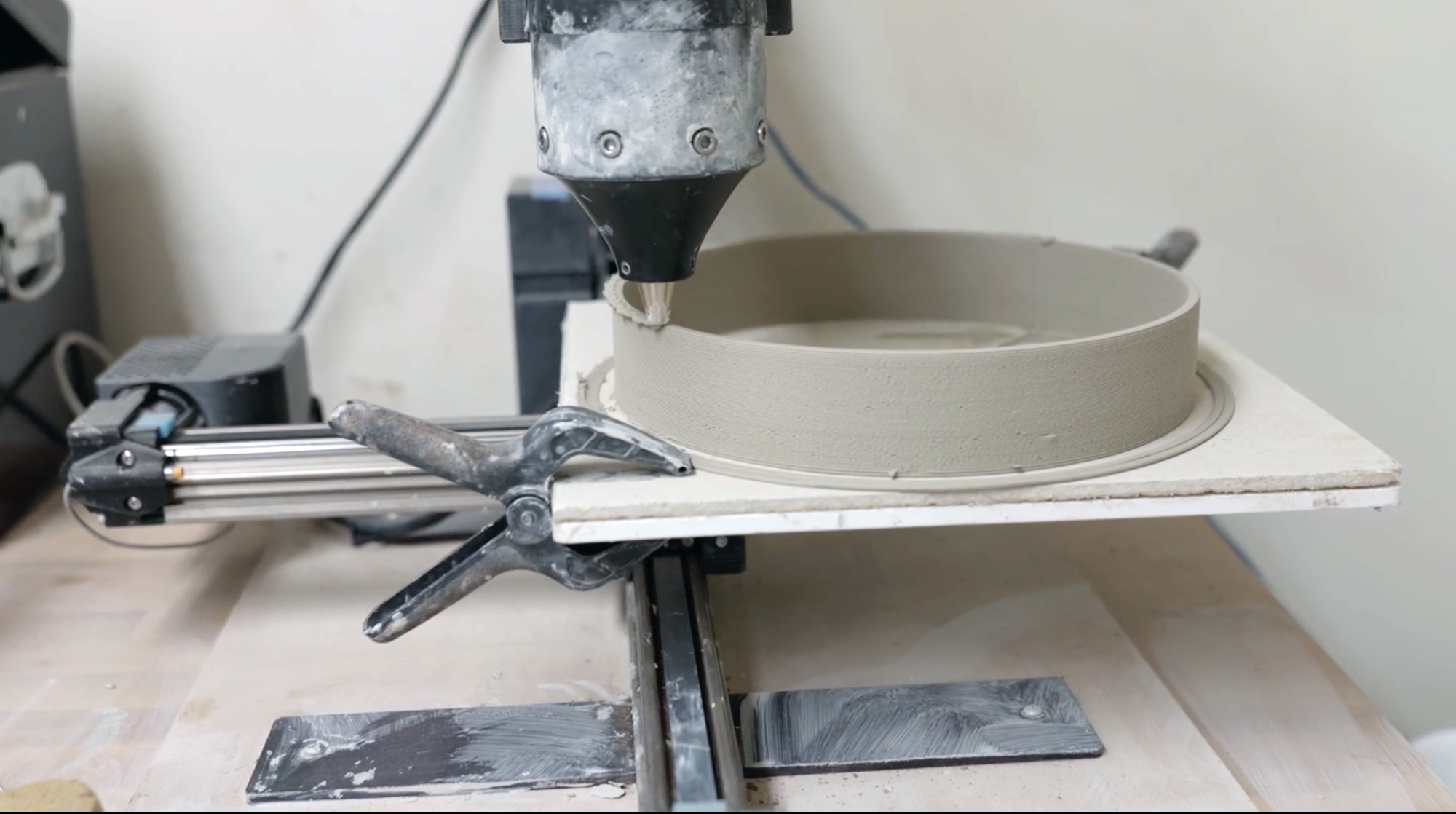

Woldenberg Art Center is now home to the Digital Ceramics Lab, a collaboration between the Tulane School of Liberal Arts Newcomb Art Department and the Tulane School of Architecture and Built Environment. With the lab’s clay 3D printers — two Potterbot Super 10 XLs — ceramics students can design and create digitally fabricated sculptures, and architecture students have a chance to explore advanced material research in parametric design.

In the lab, Grace McIntyre-Willis, a design fabrication adjunct and lecturer in the Newcomb Art Department, teaches 3D Printing Ceramics. Students learn the basics of 3D modeling and slicing software to design innovative ceramic pieces for both sculptural and utilitarian applications, pushing the boundaries of the technology's dynamic and practical capabilities. As a result of this interdisciplinary bridge between art and architecture, they have witnessed the lab become a truly collaborative environment, enriching research opportunities in materials and fabrication for ceramicists and architects alike.

“As disciplines break down the silos that separate us, novel research can be conducted; in this case, research that furthers our understanding between digital technology and what humans deem natural,” explained McIntyre-Willis.

Possibilities for the lab extend even further: “We have had ecology students experiment with the possibility of creating bio-receptive ceramic modules, architecture students creating module facade systems, two graduate students complete their thesis work exploring 3D clay fabrication, and more,” they shared. “Students have utilized 3D photogrammetry/scanning techniques to fabricate objects, printed with non-clay materials, and used unconventional ways of printing to create clay forms.”

Current courses utilizing the lab include 3D Printing Ceramics and two architecture courses — Translations: Advanced Digital Fabrication and Ecological Tectonics: Architectural Ceramic Assemblies for Climate Adaptation. In Ecological Tectonics, students embrace technical knowledge as a way to realize ecological and climate-friendly agendas in architecture, learning how to program and operate the robots to create full-scale ceramic facade components.

Bryn Creager, a 4th-year architecture student, was enrolled in both the 3D Printing Ceramics and Advanced Fabrication courses this semester. “The ceramic 3D printing lab is exciting to me because it bridges the gap between the nonphysical world of digital design and the physicality of making,” Creager shared. “The Potterbot doesn’t replace the qualities of the hand; it extends them, creating forms that the hand alone couldn’t achieve. It’s a powerful tool that encourages cross-pollination between art and architecture, connecting digital precision with material experimentation."

The Digital Ceramics Lab is open to all students who wish to experiment with digital and material fabrication, and welcomes workshops and tours from other disciplines. Students who wish to try out the lab can explore open lab hours and book a training session on the Newcomb Art Department website.